Page 147 - water-controls-for-public-commercial-places

P. 147

Solutions for thermostatic mixing valves /

REGULATIONS

HSE guidance recommends the monitoring of Legionella The monitoring of Legionella bacteria in hot

levels where there is a high risk of contamination. and cold water systems

The guidance recognises that the traditional method Guidance on compliance with the relevant parts of

of controlling the risk of Legionella development is the Management of Health and Safety at Work

to produce and distribute higher water temperatures. Regulations 1999 in public premises.

Yet, this significantly increases the risk of scalding (Source: UK Health and Safety Executive, HSG 274

at the point-of-use. Part 2, 2014).

(Source: Centre for Burns, St Joseph and St Luc It recommends: PREMIX SECURITY

Hospital, Lyon, France). - Minimum temperatures to limit the risk

rd

- At 50°C: burns in 7 seconds and 3 degree burns of development of Legionella.

in 100 seconds. - Maximum temperatures to limit the risk of scalding.

rd

- At 60°C: 3 degree burns in 3 seconds on average • At the calorifier outlet the hot water temperature

(5 seconds for an adult, 1 2 seconds for a child). must constantly be above 60°C.

• In storage equipment, water must be maintained

HSG274 Part 2 recommends the installation of at a minimum temperature of 60°C.

thermostatic mixing valves where there is a high risk

of scalding to users e.g. very young, very elderly, • At every point in the distribution system,

infirm, mentally disabled and physically disabled. hot water must be delivered to the outlet at 50°C

- Hot water should be distributed so that it reaches (55°C in healthcare facilities) within one minute

a temperature of 50°C (55°C in healthcare premises) of turning on the tap. PREMIX COMFORT

within one minute at the outlets. The HSE advises that long pipe runs between TMVs

- Thermostatic mixing valves should be installed and outlets should be avoided and should

as close as possible to the point-of-use. not exceed 2 metres in length.

The maximum temperature of sanitary hot water

HSG 274 Part 2, 2014 at the point-of-use is set at: THERMOSTATIC MIXING VALVES

HSE guidance for the control of Legionella bacteria - 44°C for bath fill (46°C if assisted)

in hot and cold water systems states that monitoring - 41°C for showers

for Legionella should be carried out: - 41°C for washbasins,

- when water is treated with biocides or when distribution with special dispensation for catering applications.

temperatures are reduced from HSE guidelines. (Source: Health and Safety Executive information

- where water treatment regime control levels are not sheet 09/12; TMVA Code of Practice, 2000).

being consistently achieved. PREMIX COMPACT

- where there is a high-risk of contamination e.g.

hospitals and care homes. Max 2m of pipework

- where an outbreak of legionellosis has been identified.

A risk assessment is required to identify the

monitoring frequency of installations for all points-

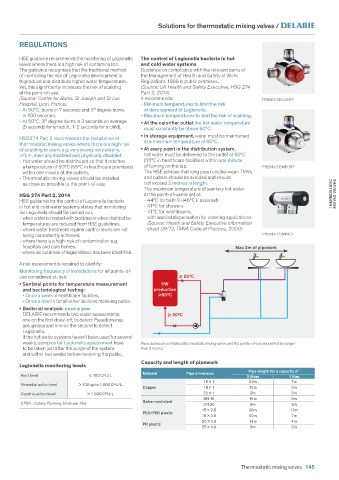

of-use considered at-risk. DELABIE recommends: ≥ 55°C

• Sentinel points for temperature measurement HW

and bacteriological testing: production

- Once a week in healthcare facilities. >60°C

- Once a month for all other facilities receiving public.

• Bacterial analysis: once a year

Two water assessments: ≥ 50°C

one on the first draw-off, to detect Pseudomonas

aeruginosa and one on the second to detect

Legionella.

If the hot water systems haven’t been used for several

weeks, samples for Legionella assessment have Pipes between centralised thermostatic mixing valves and the points-of-use should not be longer

to be taken just after the purge of the system than 2 metres.

and within two weeks before receiving the public.

Legionella monitoring levels

Alert level < 100 CFU/L

Remedial action level > 100 up to 1,000 CFU/L

Curative action level > 1,000 CFU/L

CFU/L: Colony Forming Units per litre

Thermostatic mixing valves 145