WATER CONTROLS FOR PROFESSIONAL CATERING

A professional range for intensive use

Subject to high levels of demand, the professional catering controls have been designed to withstand the stresses of intensive use: flow rate up to 100 lpm for a rapid filling of large pans and sinks, ergonomic shockproof control levers which can withstand knocks from pans, pot filler taps which are robust and swivel so cooking pots can be placed easily beneath, etc.

Rapid filling

To facilitate work in kitchens, DELABIE offers a range of fittings allowing rapid filling of large pans, cooking pots or sinks. Full flow rate is achieved in ¼ turn thanks to the tap heads which avoids turning the control several times. Depending on the model chosen, the flow rate may range from 45 to 100 lpm.

Robust

All DELABIE’s professional catering controls are subject to performance tests to make sure that they will withstand high levels of stress. Their design is suitable for intensive use, especially during peak times in the kitchens. The shockproof and ergonomic levers withstand knocks from pans and are easy to grip. Tap spouts are also very robust and can swivel to allow large pans to be placed underneath for filling. The mechanisms can withstand high temperatures - hot water can reach up to 90°C in professional kitchens.

Maximum hygiene

Hygiene is a major concern in kitchens; the equipment used must therefore conform to the relevant regulations. Delabie offers a large range of non-contact controls in order to ensure optimal hygiene:

-Presence detection controls

-Non-contact controls (knee or foot-operated).

SAFETY CONTROLS

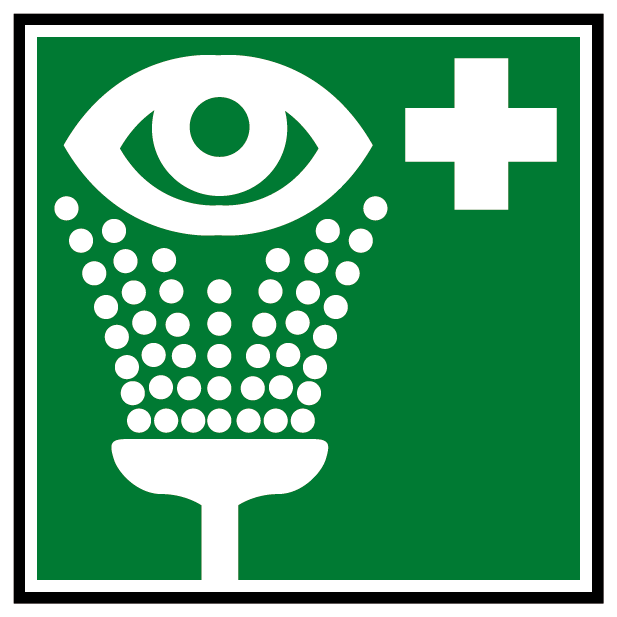

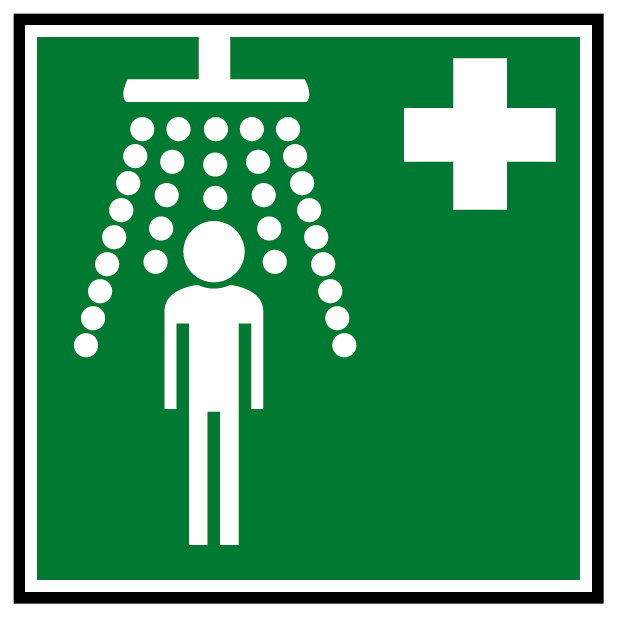

Spillages of dangerous chemicals may occur even with good safety measures in place, which is why safety equipment is mandatory in work places that are considered at risk. If the body or eyes are contaminated by chemicals, the most effective solution is to rinse with water.

Delabie also offers safety equipment such as safety showers or eye wash stations – suitable for the risks involved. They ensure a quick and effective decontamination whilst preserving the user’s comfort.

Maximum safety

DELABIE’s equipment conforms to European standards EN15154-1 and EN15154-2, ensuring maximum safety to the user.

They are mostly designed for installation inside or outside, and are fitted with a frost-free system as standard. The frost-free system on the column also ensures an effective spray with every use.

The shower head design, with peripheral diffusers, ensures an optimised spray across the whole shower. The diameter and orientation of the diffuser have been specially designed to ensure an even, conical flow.

The spray heads are fitted with aerators and stainless steel double filters to prevent any large debris in the water pipes coming into contact with the eyes. Protective caps prevent dust and other airborne contaminants entering the valve.

Robust

DELABIE’s safety equipment is made from scale-resistant and corrosion-resistant materials.

The shower head is made from shockproof ABS with peripheral diffusers. The pipes, foot control and manual control are all made from galvanised steel. The basin is made from stainless steel. The triangular, ergonomic handle and the fixing plate are made from brass.

Effective and comfort

For a rapid and effective decontamination, DELABIE’s equipment delivers large flow rates, starting from 20 lpm up to 140 lpm depending on the devices used.

The equipment is quick and easy to operate. The spray is gentle to avoid further injury to the user.