The many advantages of direct flush make it the ideal system for buildings open to the public. Here is a reminder of its advantages which are still not widely known.

Toilets with cisterns were designed for domestic use and they are not ideally suited to the demands of public buildings. However, they are often specified out of habit.

Concerns about cisterns

The main weakness of toilets with cisterns is their sensitivity to scale and impurities, the accumulation of which affects the watertight seals of the flushing system.

Depending on the water quality, a leak can occur a few months or even weeks after the toilet is commissioned. Unlike a basin tap where a leak can be detected instantly, a leak in a toilet is insidious. A leak streaming down the ceramic is very difficult to detect. Toilets are the primary source of wasted water in the system: an undetected leak can equate to a loss of up to 220m³/year, or a total of £774/year per toilet (at £3.52/m³ cold water, source: southernwater.co.uk 2017).

WC cisterns that are not used for several days pose a health risk. Standing water at room temperature, where there are also scale and impurities present, is conducive to bacterial development.These bacteria can be spread in aerosol format when the toilet is flushed, but can also spread back up the pipes and colonise the system.

Cistern flushing does not stand up well to use in the public domain. Comprising plastic components, the mechanism is subject to intensive use and, sometimes, rough handling.

Maintenance can be time consuming where there are a large number of toilets. Repairs to a leak in a recessed cistern mounted on a frame system can take a long time. Access to, and removal of, the mechanism is difficult on these models. Replacing the cistern on a frame system is difficult without breaking the partition wall.

Advantages of direct flush

Direct flush vales are designed to meet the demands of highly frequented public toilets. Hygienic, robust and effective, they reduce the risk of leaks.

Direct flush systems have no water stagnation, scale deposits or impurities, and therefore no bacterial growth.

Toilets with a cistern operate on the principle of gravity. The flush is less powerful than for a direct flush system, which uses the pressure in the system and guarantees a clean bowl in a single flush.

The direct flush system allows successive flushes if necessary and is immediately available for consecutive users. There is no waiting time for a cistern to fill.

In hotels, offices and healthcare facilities, a short 7-second flush, with no refill time, enhances the acoustic comfort of users.

Architects appreciate the compact nature of the direct flush system. There is no need to allocate prime space to a cistern.

Diameter matters

Contrary to popular belief, a toilet with a cistern can be replaced by a direct flush system during refurbishment. If there is an accessible service duct and the flush pipe is close, e.g. in a hospital, retirement home or office building, only the final connections need to be changed in most instances.

Regarding supply pipes, the recent revision of the French regulation DTU 60.11 confirms that there is a different calculation for direct flush valves compared to toilets with cisterns. It determines that the pipework diameters for direct flush toilets are similar to those for toilets with cisterns. Indeed, the flush and refill time for cisterns is much longer than the usage time for direct flush valves (which only lasts a few seconds).

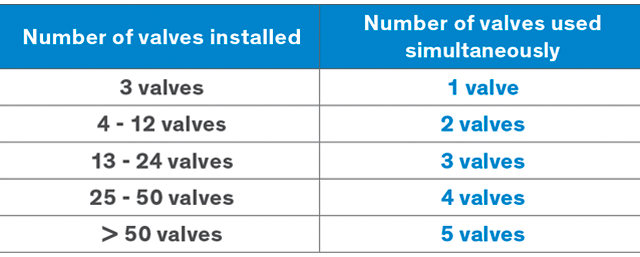

The DTU refers to the manufacturer’s data for calculating basic flow rate (1 litre/sec. for DELABIE’s direct flush toilets). It uses the Delebecque system for calculating the coefficient of simultaneity (see table opposite).

The diameter of the pipes calculated in this way is not very different from that of cisterns, contradicting the general concern about supply pipe diameters for direct flush.

Adapted products

For nearly 30 years, DELABIE has been developing direct flush toilets for commercial applications.

The mechanisms and controls, with no fragile plastic parts, are shock resistant and vandal resistant. They have a lifespan of more than 500,000 operations.

On DELABIE’s direct flush valves fitted to frame systems, maintenance is limited to a simple standard cartridge exchange. It is also made easier by direct access to the mechanism, without removing the tap.

For improved water consumption, the TEMPOFLUX 2 direct flush is available in 3L/6L dual flush version which can be adjusted to 2L/4L. The building owner can optimise their building design and achieve the highest standards of ecolabels (HQE, BREEAM, LEED, etc.).

They chose DELABIE’s direct flush...